- Home

- Industries

- Power Generation

- Fossil Fuel

Fossil Fuel

Providing fossil fuel power plants with severe service ball valves for high temperatures and high pressures.

Modern fossil fuel plants are highly complex, custom-designed systems. Emerging boiler technologies and progressive system upgrades are increasing plant capacities and changing the operating landscape. These innovations include higher temperatures and pressures found in advanced super-critical and ultra super-critical plants.

Modern fossil fuel plants are highly complex, custom-designed systems. Emerging boiler technologies and progressive system upgrades are increasing plant capacities and changing the operating landscape. These innovations include higher temperatures and pressures found in advanced super-critical and ultra super-critical plants.

At MOGAS, we have partnered with major power producers and have applied aggressive research & development efforts in metallurgy, design and surface coatings to design and manufacture high pressure valves and high temperature valves that answer their specific needs. Because MOGAS is committed to protecting our customer’s critical equipment, continuous product innovation is a vital part of the way we do business.

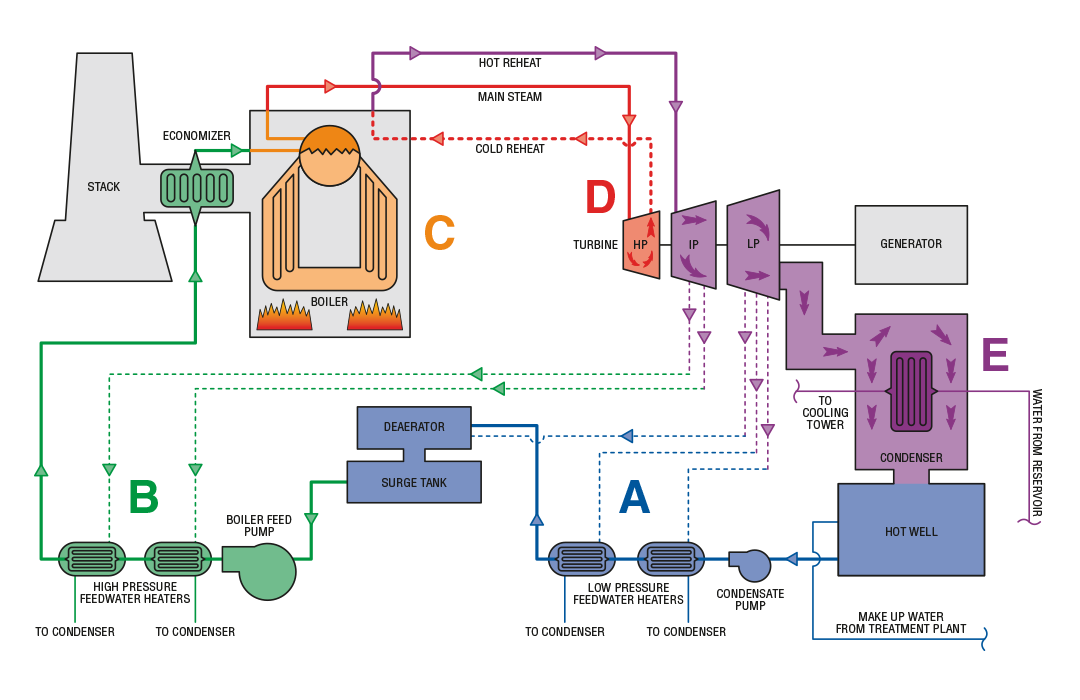

MOGAS Valve Installations — Typical Fossil Fueled Power Plant

-

- Deaerator Vent / Instrument Isolation

- Isolation Valves on Bypass Lines

- Extraction Steam Drain / Orifice Isolation

- Feedwater Heater Drain / Vent

- Shell Side Instrument Isolation

-

- BFP Discharge Isolation

- BFP Shell or Case Drain

- BFP Minimum Flow Isolation

- BFP Warming Line Isolation / Drain

- Reheat / Superheat Isolation

- Feedwater Heater Isolation / Bypass

- Bypass Valves

- Shell Side Vent / Instrument Isolation

- Tube Side Drain / Instrument Isolation

- Economizer Drain

-

- Drum Blowdown Root Valve / Isolation Vents

- Drum Instrument Isolation

- Sight-Glass Isolation / Drain

- Water Wall Drain / Vent / Instrument Isolation

- Tandem Blowdown

- Mass Boiler Blowdown

- Primary Superheat Drain / Vent / Instrument Isolation

- Secondary Superheat Drain / Vent / Instrument Isolation

- Reheat Drain / Vent / Instrument Isolation

- Superheat Spray Isolation

- Superheater Spray Automated Blocking

- Reheater Spray Isolation Blocking

-

- Supply & Extraction Systems

- Main Steam Drain / Root Drain

- Main Steam Before & After Seat Drain / Root Drain

- Main Steam Lead Drain / Root Drains

- Turbine Bypass Isolation

- Bypass Valves

-

- Supply Extraction Systems

- Hot Reheat Drain / Root Drain

- Hot Reheat at the CRV Drain / Root Drain

- IP & LP Turbine Extraction Drain / Orifice Isolation

Auxiliary Systems

-

- Sootblowing Header Isolation / Blocking

- Sootblower Regulator Automated Isolation

- Blocking Valves after the Control Valves

- Sootblower System Crossover Header Isolation

- Sootblower Bank Isolation

- Individual Sootblower Isolation

- Air Heater Sootblower Steam Supply Line Shutoff

- Sootblower Thermal Drains / Bypass

-

- Main Steam Supply Isolation Valve

- HP BFP Steam Supply Drain / Root Drain

- HP BFP Below & Above Seat Drain / Root Drain

- Isolation Valves on the Bypass Lines

- Extraction Steam Supply to LP BFP Turbine Drains

- LP BFP Below & Above Seat Drain

-

- Inert Steam Inlet to Pulverizer Blocking / Automated Isolation

- Steam Supply to Inerting System Pressure Regulator Isolation

- Extraction Steam Supply Line to the Inerting Steam Header Drain

- Isolation Valves on the Bypass Lines

- Inerting System Steam Header Thermal Drain