- Home

- Industries

- Other Industries

Other Industries

Providing innovative valve solutions for specialty industries

When you think of MOGAS severe service valves, the power, refining, mining or petrochemical industries might naturally come to mind. But did you know that MOGAS supplies innovative valve solutions to a variety of specialty markets as well?

When conventional valves cannot withstand the demands of extreme, highly critical applications or punishing conditions, leaders in the food processing, aerospace and pulp and paper industries look to MOGAS to help ensure the integrity of their equipment and processes.

And just as MOGAS works with its clients in other industries to customize solutions, MOGAS also works with its specialty clients to design and engineer valves that specifically address their unique needs.

-

MOGAS has experience working in tandem with leading aerospace companies to identify solutions that address highly critical applications that are unique to the industry. In one case, MOGAS supplied valves ranging in size from 1½ to 8 inch bores to help an aerospace company test rocket engines. The valves had to handle gaseous hydrogen and nitrogen, liquid hydrogen, and helium. With up to 10,000 psi differential pressure across them, the valves had to open in less than one second and then rapidly close to seal tightly at the completion of the test. We are pleased to report that our MOGAS valves passed the test with space-high marks.

-

MOGAS’ first custom designed valve was for a coffee plant near downtown Houston.

MOGAS’ first custom designed valve was for a coffee plant near downtown Houston.

Many leading consumer food producers use MOGAS valves in supercritical and highly advanced extraction applications where the technology of molecular restructuring assists to decaffeinate coffee and tea, remove nicotine from cigarettes, separate hops for beer, or remove cholesterol from cooking oil. Because MOGAS valves can withstand high cycling, cryogenic temperatures and rapid operation, food producers depend on their superior performance to ensure the integrity of their processes and the safety of their people.

-

Within the pulp and paper industry, MOGAS ball valves have proven to be a superior alternative to traditional valves. While other valves struggle to effectively handle blow lines, green and black liquor, batch and continuous digesters, liquor heater isolation, high and low pressure steam injection, drains and soot blowers, MOGAS has adapted field-proved design features from other industries to engineer strong cast and forged valves that meet the harshest demands of the pulp and paper industry.

Oxygen and Precision Cleaning Services (MOGAS Surface Technologies)

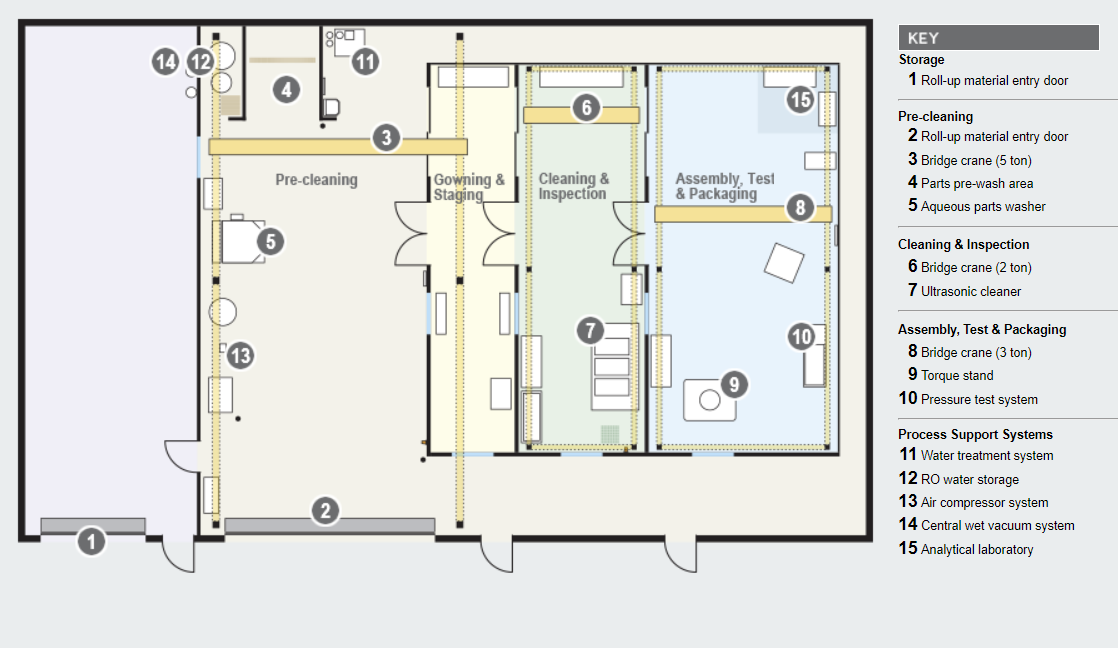

MOGAS Surface Technologies provides cleanroom services and precision cleaning of valves and critical parts to minimize non-volatile residue (NVR) for valves and critical components. Specific applications in oxygen-rich environments require the absolute removal of impurities that degrade a product or that can be a safety hazard to equipment — or even worse, a danger to your people.

Our qualified technicians follow exacting cleanroom protocol and industry standards in a specifically built facility. Each job is fully documented to define, control and monitor processes such as material flow, cleaning details, inspection results and packaging and labeling.

Tour the cleanroom facility layout through our interactive map.